CAMS

Chesapeake Area Metalworking Society

Review of 25 March 2008 Meeting

Mason District Governmental Center

6507 Columbia Pike

Falls Church, VA

contributed by Charles Keeney

Editors Note: Many of the photographs appearing in this month's report are courtesy of Tex Rubinowitz and are noted as such. Thank you, Tex, for the outstanding job.

The pre-meeting festivities on March 25, 2008 CAMS began with the usual indoor tailgating and camaraderie. Dave Bluett was selling chickens in the form of setscrews and cap screws. Al Haraq was selling aluminum sheet and other goodies. Chris Daniel was offering assortments of setscrews and knurled thumbscrews and nuts as well as metric thread gauges. Paul Milsback was offering an assortment of treasures. Alan Weber made the trip from Richmond with a basket chock full of aluminum and brass stock as well as enough tooling and the like to cover several table tops.

Part of Alan Weber's offerings for the evening.

Chris Helgesen called the formal meeting to order around 8:00 PM and 29 members were counted in all including early departures and late arrivals. Especially heartening was to see several members who had been absent from the most recent meetings as well as several first and second time attendees. Chris called Steve Stallings forward to discuss a matter that affects a number of CAMS members. Steve noted that over the past several months he has been attempting to ensure that all CAMS members receive uninterupted service from the CAMS mail server. Steve reported that changes by Microsoft to .Hotmail and .MSN accounts has now reached the point where their trigger happy spam blocking makes it impractical to attempt to continue to accommodate those mail account providers. Steve urged anyone with a .Hotmail or .MSN account to seek a new e-mail service provider for receiving the CAMS list. The discussion then spread to status of CAMS list server and the CAMS web site.

.jpg)

CAMMERS Share a Humorous Moment Early in the Meeting. That is the back of Reed's Joltmeter in the Foreground. Photo by Tex Rubinowitz.

Tex Rubinowitz followed Steve. Tex informed everyone that he was still moving forward with the Gear Cutting Special Interest Group (GCSIG). Tex envisions that the GCSIG will come together in the near future, will explore all the practical aspects of generating gears in a home shop environment, and then disband after the members feel that they have explored the topic to the maximum extent practicable. A number of CAMS members have stated an interest in participating in the subgroup. Tex also mentioned a project that he had in mind to tutor neophyte CAMMERS in selected machining topics. Rich Kuzmack in turn followed Tex and mentioned that he had negotiated a $100 reduction in the price of Alibre CAD/CAM software through the end of March. According to those present, this package is parametric and supports subassemblies. Anyone interested in such a deal should contact Rich.

It was then reported that Jim Beaver and Max Mitchell were having their annual tag sale in Silver Run, MD on April 3 though April 5. The tag sale is basically a yard sale but more formal with almost everything being pre-priced. Chris Helgesen then spoke briefly about gear meet/metal meet.

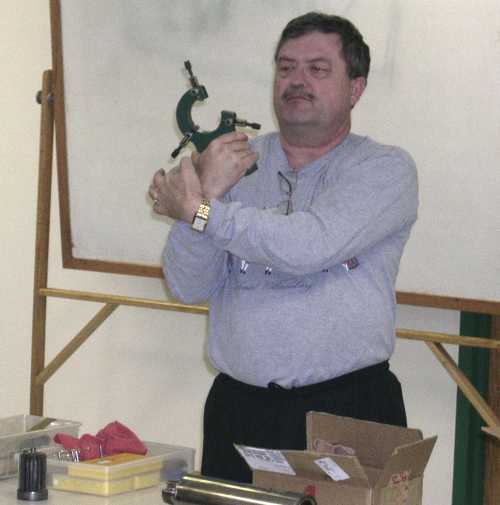

The first of the evening's presentations was given by Bruce Buckner who told of a small engine project on which he has been working. Bruce spoke about the challenges of holding a finned cylinder in his Grizzly 11" X 36" lathe. Bruce said that he realized that he needed to use a steady rest to support the cylinder while it was being turned on the lathe but when he pulled out his steady rest he realized that the finned cylinder was too large to fit into the steady rest. Bruce then spoke about how he modified his steady rest to accommodate the finned cylinder's outside diameter. Bruce passed around his modified steady rest and the finned cylinder as well. Dave Bluett remarked at this point that the original steady rest on his Grizzly 12" X 36" lathe was improperly machined in the area that contacts the lathes bed so Dave contacted Grizzly and requested a replacement. Grizzly sent a replacement promptly but Dave reported that the replacement suffered from the same flaw and so Dave reported that he just gave up hope of having Grizzly remedy the problem.

Bruce Buckner Appears to Show How to Use a Steady Rest as Nunchucks. Bruce's Finned Cylinder is at the Bottom Left of the Photo for Scale. Photo by Tex Rubinowitz.

Close-up of Bruce's Finned Cylinder.

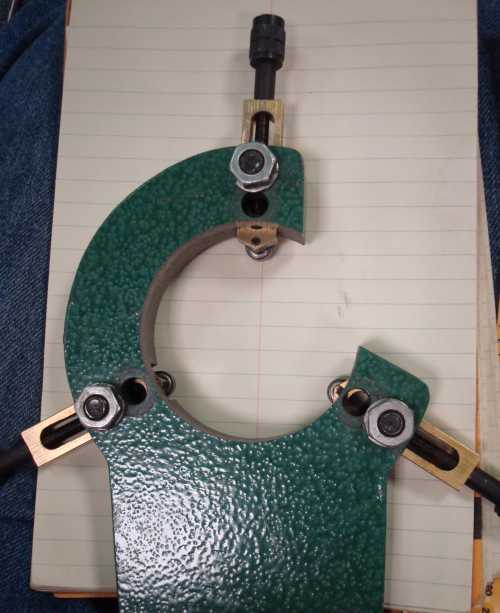

Bruce's Modified Grizzly Steady Rest.

A Close-up of Bruce's Modified Grizzly Steady Rest.

Dave assumed the floor at this point and told the club about some B&S No. 9 collets that he purchased on eBay at a remarkably low price - approximately $10.00. Dave passed several around and the finish was certainly a nice ground finish. Dave had not yet had an opportunity to use them so the degree of run out was not known. Dave also noted that he had several metal storage cabinets for sale at very low prices.

.jpg)

Dave Bluett Ponders a Question From the Floor. Photo by Tex Rubinowitz.

A Close-up of One of Dave Bluett's B&S No. 9 Collets.

Unidentified Addled Man (in Red Cap) Who Apparently Wandered in Off the Street, Asks If He Will Have to Sing Along With the Prayer Meeting in Order to Get the Free Meal at the End of the Service. ...The Meeting Continued After an Embarassing Silence. Photo by Tex Rubinowitz. <sources now confirm that the unidentified man also wrote this meeting review>

Chris Helgesen spoke next about his Hurco rehabilitation process. Chris noted that he now has coordinated 3-axis movement, power brake on the spindle, automatic oiler, and several other features working although the spindle is slightly bent. Tex volunteered to show Chris a technique to straighten the spindle using only feeler gauges but Chris indicated that he wanted to pursue another solution first. Chris finished by speaking about the Universal 200 tool holders that the Hurco uses.

Chris Discusses the Bent Spindle of His Hurco CNC Mill.

Tex took control of the floor at this point and spoke to the club members about his project to make new cross slide and compound slide micrometer screws and dials for South Bend 9" and 10" lathes. Tex has spent considerable time perfecting his design and technique and through his generosity several CAMMERS have these handsome and useful devices on their own lathes. Tex passed several finished examples around the audience as well as one mounted to the compound. Tex has also been generously sharing his knowledge on-line on the South Bend forum on the Practical Machinist web site.

At 9:00 p.m. Tex Explained His Process to Produce New Compound Screws.

Tex Displays the New Compound Screw and Dial Installed on the Compound.

Tex's Shop-Built Screw and Dial Beside a South Bend Original.

Close-up of New Compound Screw and Dial Installed on the Compound.

A Close-up Showing the Detail of Tex's Work.

The Toolpost and Bit Used by Tex to Cut the Screw Thread.

.jpg)

Tex Later Shared This Photo of the Machining Setup to Cut the Acme Thread on His South Bend Heavy 10 Lathe. Photo by Tex Rubinowitz.

Taking the floor after Tex was Reed Martin who had brought his Joltmeter and a sterling engine that he scored at a flea market. Reed had crossed the Potomac to share these items with the attendees that could not make it to the February past meeting in Maryland. Following Reed was Alan Weber who had brought along a hex key wrench that appeared to be about 2" or more across flats. After Alan, Dan Stafford told the club about some problems that he was encountering with his tapping head and several knowledgeable suggestions were offered by the audience. Charles Lessig then shared an 1880's advertisement featuring a cast iron stove.

.jpg)

Reed Shares Information About the Joltmeter (Left) and His Sterling Engine (Right). Photo by Tex Rubinowitz.

.jpg)

That is not a tailpipe that Allan is holding; it is an approximately 2+" Allen Wrench. Photo by Tex Rubinowitz.

.jpg)

Charles Lessig Speaks About an Old Catalog for Cast Iron Stoves. Photo by Tex Rubinowitz.

The announced theme for the meeting was tools and techniques for making holes. Much of what follows is contributions by various members on this topic.

Steve Stallings returned to the dais at this point and presented a number of unusual and interesting items to the audience. These items included a step drill, bits for making other than round holes, a holehog for a magnetic drill, and an Aloris toolpost-mounted drillchuck holder that had several CAMMERS drooling. He also spoke in detail about reamers (limit to 1 or 2 thou cuts), machine, hand and bridge reamers, that reamers cut on the tapered end and not on the longitudinal edges. It is the longitudinal edges (which can be straight or spiral) that serve to keep the reamer properly located in the middle of the hole. Steve ended his talk by discussing the processes of honing, which is a process using a stone that is firmly oriented, and lapping, which is a process using loose aggregate. Charlie Savich noted during the discussion on reamers that some knowledgeable metalworkers prefer spiral fluted reamers over straight fluted reamers because the straight fluted reamers are considered to be more likely to wander during the reaming operation.

Steve Stallings Broaches a Subject While Kevin Brady Listens In.

Steve with Flycutter in Right Hand - Toolbit is Protruding at Bottom and Towards Steve's Left.

Steve's Toolpost Mounted Lever Operated Drill Chuck Ram. The Jacobs Taper is Seen to the Left.

Steve's Toolpost Mounted Drill Chuck Ram With the Linkages Articulated to Show Principle of Operation.

Chris Helgesen displayed a boring head and spoke about them for a period. According to Chris, Bridgeport and most European brands are good choices for quality and that Tree Machine Tool made a facing head that is considered to be a superb example. The Tree facing head is capable of boring a taper. Chris also showed a Silver and Demming drill bit and explained that these bits have the virtue that all bits in a set use the same shank size and this translates into rapid tooling changes because the drill chuck only needs to be opened wide enough to allow insertion and withdrawal of the drill bit from the drill chuck. Chris wrapped up his presentation with discussion about how trepanning tools work and should be sharpened.

Chris Notes Features of Quality Boring Heads.

Cogsdill Internal Burnisher.

Puzzle - some sort of floating toolholder.

Fred Schirrmacher spoke next. Fred began by putting the situation in context: his lathe is a 1929 South Bend 9" X 30" with a 1/2 HP motor. As such, Fred noted that the lathe can quickly become taxed when performing drilling operations. Fred cited a report that found that 75% of the energy expended in drilling with a conventional twist drill is expended by the center flat or web. Anything that can reduce this amount can be used for other purposes such as being able to use a larger size bit until the stall point is reached. According to Fred, many of the proprietary drill bits are difficult if not impossible for the average shop to sharpen because to the varied and varying angles used by those bits. Fred also reminded the group that it is wise practice to keep a set of bits just for plastic and brass because those materials require either very sharp bits or bits with the leading edge "broken". Tex Rubinowitz noted that he has resorted to using soda straws and blowing air on bits using lung power when cutting plastic to keep the temperature of the bit below the melting point of the plastic being machined. Fred then noted that a viable choice may be to use a hand drill to keep the speed below 300 RPMs. Fred's next topic was to share a valuable tip about an effective way of cutting ceramic tile that he learned from an expert. First, outline the cut on the ceramic tile with a felt tip or similar marker. Next using a hammer and a center punch, gently tap along the line using light stokes but with enough force to that it scores or fractures the vitreous surface. The next step is to carefully break the pieces apart long the scored line. Finally, clean up the surface by stoning the edges. Fred's final topic was to speak about "D" bits and he noted that reamers may be made this way. Fred noted that he made a Metal Lathe Accessories face plate using a D bit/reamer.

Yes, Virginia, that is a Tailstock Die Holder that Fred is Discussing.

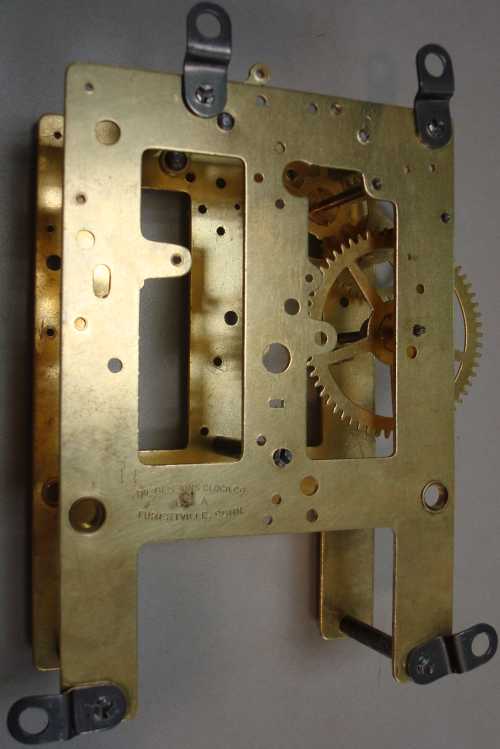

Stan Stocker presented his talk last to the assembled members and it was certainly well worth the wait. Stan spoke about some of the challenges that confront horologists as they repair old clocks. For those who are unaware, Stan has been repairing clocks for years near Front Royal and so there was a high level of interest in what Stan was going to share. Stan is also an engaging and animated speaker making his presentation all that much better. Stan spoke about various clockmaking techniques, clock bushings, burnishers, and repivoting - the reconditioning of pivots - amongst a variety of horological related information. Stan noted that clocks are astonishingly sloppy compared to typical tolerance standards of thousands or even tens-of-thousands of an inch such as most machinists are used to dealing with. Stan noted that too close tolerance will result in excessive friction, which the typical mainspring cannot power more than a few minutes. Stan noted that one principle that helps clockmakers is that clocks gear up; not gear down. Stan spoke about commercial practices and then showed the Club a bushing device that he fabricated in his own shop. Stan also shared a technique told to him by Jerry Kieffer to readily align a center point when using a Sherline mill, a drill chuck and a light. Stan also recommended to the club that they grind a radius or dome on the hammer end of punches so that a mistrike will have less chance of damaging the work piece. Other topics addressed by Stan were to search out a good jewelers saw (he recommended considering a Robay); how to replace a missing tooth in a gear (this alone made a long drive to the meeting worthwhile); and a "one-dip" cleaner.

Stan Stocker Discusses Horological Restorations.

Stan Stocker Explains a Technique Told to Him by Jeffy Kieffer.

An Example of Stan's Repair Work.

Close-up of Stan's Repair Work.

With that, the meeting was adjourned and the members were again free to roam about and engage in one-on-one conversations or to disperse towards home or the traditional midnight supper at a nearby restaurant.

The editor requests that factual errors be brought to his attention.

| Home | Mailing List | Meetings | Meeting History | Events | Event History | Tuckahoe | Resources | Links |